ZNC Series JM500+AZ50DR+D500

Developed by a group of top engineers and technicians with rich on ground and theoretical experience in the field of EDM, JM500+AZ50DR+D500 renders superb engineering supremacy and unmatched mechanical features to outstand others.

- Specs

- Accessories

- Features

- Controls

- Cut Samples

- Video

- Inquiry

MACHINE UNIT & DIELETRIC TANK UNIT

| ITEM | UNIT | JM500+AZ50DR+D500 |

|---|---|---|

| Work table size | mm | 750 × 520 |

| X travel | mm | 500 |

| Y travel | mm | 400 |

| Z travel | mm | 300 |

| W travel | mm | 200 |

| Ram platen to work table | mm | 150 ~ 650 |

| Max. electrode weight | kgs | 150 |

| Max. workpiece weight | kgs | 1200 |

| Work tank ( W × D × H ) | mm | 1250 × 660 × 420 |

| Weight of machine unit | kgs | 1800 |

| Machine Outside dimensions ( W × D × H ) | mm | 1645 × 1900 × 2455 |

| Max. Machining Current | A | 50 |

| Total Power Input | KVA | 4.5 |

| Max. Metal Removal Rate | mm3 / min | 390 |

| Electrode Wear Ratio | % | 0.25 |

| Best Surface Roughness | µm Ra | 0.20 |

| Net Weight | kgs | 180 |

| Outside Dimensions ( W × D × H ) | mm | 580 × 725 × 1730 |

| Dielectric tank capacity | L | 570 |

| Dielectric tank pump | HP | 0.85 HP × 1 |

| Dielectric tank net weight | kgs | 150 |

| Dielectric tank filter method | Paper filter | |

| Dielectric tank outside dimensions ( W × D × H ) | mm 950 × 1400 × 1100 |

* All specification and design are subject to change without notices.

STANDARD ACCESSORIES

| Paper filters 1 set |

| Tool box 1 pc |

| Flushing nozzle 1 set |

| Drill chuck 1 pc |

| Clamping kit 1 set |

| Electrode holder 1 pc |

| Halogen machine work lamp 1 pc |

| Leveling pads 1 set |

| Digital readout 1 set |

| Up cutting set |

OPTIONAL ACCESSORIES

| Auto fire extinguisher |

| CNC orbit-cut system ( For AZDR / NZ series ) |

| Permanent magnetic table |

| Dielectric cooler |

| Spare PCB set |

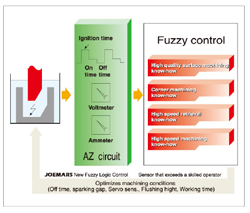

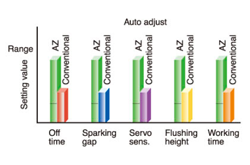

THE JOEMARS NEW FUZZY LOGIC CONTROL SYSTEM CONCEPT

| JOEMARS New Fuzzy Logic Control |

| Sensor that exceeds a skilled operator / Optimizes machining conditions ( Off time, sparking gap, Servo sens., Flushing hight, Working time ) |

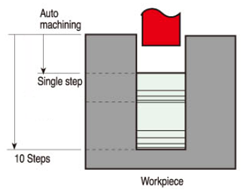

NEW Z NC PROGRAMMABLE FOR AUTO MACHINING

| From Rough To Fine Finishing |

| Total of 50 programs, each program can do a single step, or a maximum of 10 steps machining ( option ) and each step includes 12 kinds of machining parameters. By using the JOEMARS Fuzzy Logic Control System, the operator can get a total of 9600 sets of machining parameters which can also be modified at any time during sparking without affecting the stored parameters. |

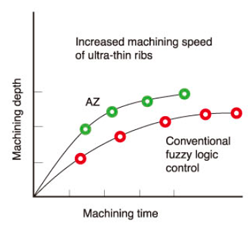

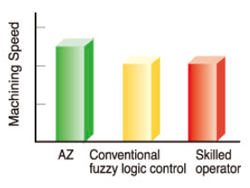

MACHINING SPEED :

| 10% - 45% faster than conventional mode. |

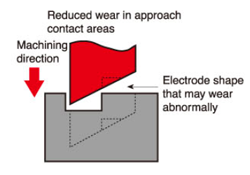

LOWEST ELECTRODE WEAR.

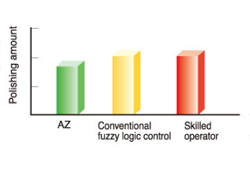

SURFACE FINISHING :

| A much higher quality machining surface that requires a minimum amount of polishing reduced by 25%. |

SHORTEST MACHINING PARAMETERS SETTING TIME

| Only input:(1) Machining materials, (2) Electrode size, (2) Electrode wear & (4) Peak current. Then the best machining parameters will be auto set to start machining from rough to final surface finishing automatically. |

NEW “4A” EQUIPMENT : ANTI-ARCING AUTO ADJUSTMENT

| The JOEMARS Fuzzy Logic Control System will auto monitor & adjust the machining parameters in the event of a poor machining condition. Once the condition has been cleared it will auto return to the pre-set machining parameters to achieve the best performance. |

FASTER MACHINING SPEED OF ULTRA-THIN RIBS.