Wire Cut EDM WT 455

Developed by a group of top engineers and technicians with rich on ground and theoretical experience in the field of wire cut edm, WT 455 renders superb engineering supremacy and unmatched mechanical features to outstand others.

- Specs

- Accessories

- Features

- Controls

- Cut Samples

- Video

- Inquiry

MACHINE UNIT & FILTRATION SYSTEM

| ITEM | UNIT | WT 455 |

|---|---|---|

| Max. work piece dimension ( W x D x H ) | mm | 900 × 650 × 245 |

| Max. work piece weight | kgs | 550 |

| X travel | mm | 450 |

| Y travel | mm | 300 |

| Z travel | mm | 250 |

| U travel | mm | 100 |

| V travel | mm | 100 |

| Drive system | AC servo motor | |

| Wire diameter | mm | Ø 0.10 ~ Ø 0.30 ( standard ) |

| Max. taper angle | mm | +/-20° / 80mm |

| Machine net weight | kgs | 2100 |

| Filter system capacity | L | 700 |

| Filter element | Paper filter | |

| Ion exchange resin capacity | L | 14 |

| Water quality control | Auto | |

| Water temperature control | Auto | |

| Machine layout dimension ( W x D x H) | mm | 2236 × 2308 × 2070 |

* All specification and design are subject to change without notices.

STANDARD ACCESSORIES

| Auto vertical alignment lig / 1set |

| Tool kit / 1set |

| Wire guide Ø 0.25 mm – 1set |

| Brass wire roll Ø 0.25 mm / 1 set |

| lon exchange resin / 1 set |

| Filter element / 1 set |

OPTIONAL ACCESSORIES

| Wire tension meter |

| Wire guide set Ø ( 0.10 mm / 0.15 mm / 0.20 mm / 0.25 mm / 0.30 mm ) |

| Dielectric cooling unit |

| Consumable parts ( wire, flushing nozzles……etc. ) |

| Super fine finish circuit |

| Linear scale ( for X & Y axis ) |

| Auto voltage regulator ( AVR ) |

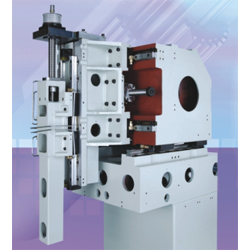

MECHANICAL DESIGN FEATURES

| Each axis uses precise ballscrew and linear motion guide. |

| AC servo motor directly go through coupling to drive the ballscrews. |

| The work table is manufactured from stainless design to ensure best maintenance. |

| The U,V axes located upper from the column to offer accurate stability, it can reach precise taper machining when facing high wire tension and high water pressure. |

| High rigidity design, and well thermal balance are used for precision machining. |

| Heavy-duty wire spool shaft design for ease of maintenance. |

| Lower arm thermal cooling system ensures high stability. |

| Hardened Stainless work tank base, enhance rigidity and support sealed, well-balanced, box-type design casting of the machine body ensures high thermal balance stability. |

| Each axis uses high precision C1 class ball screws with manual single shot lubrication system on the X and Y axes fitted as standard. |

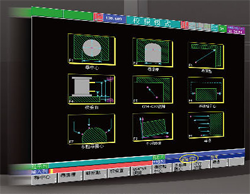

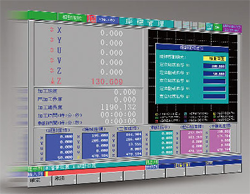

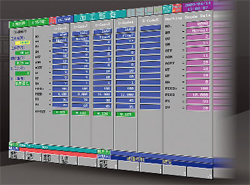

DOS CONTROLLER 1

| Applies high tech CPU control and high stability industrial professional computer, provides powerful NC function and carry out the high accuracy machining result. Sufficient and high efficient operation panel shows new generation PC-BASED super powerful way of control system. |

DOS CONTROLLER 2

| Provide easy operation and checking mode. |

DOS CONTROLLER 3

| Insert the zero point or positioning function. |

DOS CONTROLLER 4

| Data base for different material work piece and machining condition parameter and settings can be the reference for the operators. |

DOS CONTROLLER 5

| CF card available, replaces old-fashion 3.5” hard-disk and provide bigger memory capacity of machining data. |

CNC UNIT & PROCESSING POWER SUPPLY

| Controller device:Industrial grade Pentium 2 IPC |

| Memory device:CF CARD |

| Screen display:12.1" 800 x 600 Colorful TFT LCD |

| Input means :Keyboard, RS232, CF card, Ethernet |

| Servo control means Fully-closed circuit AC servo control. |

| No. of axis control:5 axes |

| Min. Instruction value:0.001 mm |

| Max. Instruction value:9999.999 mm |

| Pattern rotation:0 ~ 360° |

| Processing condition:9999 sets |

| Discharge power supply:AC MOSFET |

| Surface roughness:0.3 ~ 0.4 μmRa |

| Intelligent ignition power supply:Ultra-thin, thick plate |

| Electricity required:3 Phase, AC220V / AC380V / AC415V / AC440V , 18KVA |