CNC Series JMNC60+NP100+D60

Developed by a group of top engineers and technicians with rich on ground and theoretical experience in the field of EDM, JMNC60+NP100+D60 renders superb engineering supremacy and unmatched mechanical features to outstand others.

- Specs

- Accessories

- Features

- Controls

- Cut Samples

- Video

- Inquiry

MACHINE UNIT & DIELETRIC TANK UNIT

| ITEM | UNIT | JMNC60+NP100+D60 |

|---|---|---|

| Work table size | mm | 900 × 650 |

| X travel | mm | 600 |

| Y travel | mm | 400 |

| Z travel | mm | 350 |

| Ram platen to work table | mm | 255 ~ 605 |

| Max. electrode weight | kgs | 150 |

| Max. workpiece weight | kgs | 2000 |

| Work tank ( W × D × H) | mm | 1300 × 900 × 430 |

| Weight of machine unit | kgs | 3000 |

| Machine Outside dimensions ( W × D × H ) | mm | 1870 × 2495 × 2320 |

| Max. Machining Current | A | |

| Total Power Input | KVA | |

| Max. Metal Removal Rate | mm3 / min | |

| Electrode Wear Ratio | % | |

| Best Surface Roughness | µm Ra | |

| Net Weight | kgs | |

| Outside Dimensions ( W × D × H ) | mm | |

| Dielectric tank capacity | L | 800 |

| Dielectric tank pump | HP | 0.85 HP × 2 |

| Dielectric tank net weight | kgs | 200 |

| Dielectric tank filter method | Paper filter | |

| Dielectric tank outside dimensions ( W × D × H ) | mm | 1200 × 2000 × 1100 |

* All specification and design are subject to change without notices.

STANDARD ACCESSORIES

| Paper filters 1 set |

| Tool box 1 pc |

| Flushing nozzle 1 set |

| Drill chuck 1 pc |

| Clamping kit 1 set |

| Electrode holder 1 pc |

| Halogen machine work lamp 1 pc |

| Leveling pads 1 set |

OPTIONAL ACCESSORIES

| Auto fire extinguisher |

| Permanent magnetic table |

| Dielectric cooler |

| Auto Electrode Changer ( For CNC EDM only ) |

| 3 or 4 Tools for JMNC32A & JMNC43A |

| 5 Tools for JMNC50 & JMNC53 / JMNC53P |

| 6 Tools for JMNC60 ~ JMNC2210S |

| C-axis ( For CNC EDM only ) |

| Spare PCB set |

FEATURES

| Industrial grade PC based CNC controller |

| 12.1” TFT LCD color panel |

| Dialogue programming or GM code programming |

| Background editing |

| User Macro function |

| Multi language support |

| Machining path display |

| MPG positioning and discharging alignment |

| Multi-holes macro programming: Linear / Circular / Array / Arbitrary Multi-holes |

| Multi-conditions macro programming for finish machining |

| 1000 machining condition tables with 1000 conditions in each table |

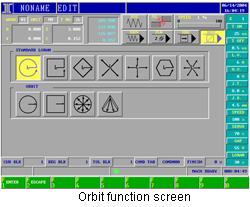

| 17 kinds of Loran & Orbit function |

| LWF sparking circuit able to control the peak current rising slope, reduce the corner wear |

| Tracking mode OFF-TIME control circuit to prevent Arcing |

| All PC boards are sectioned in modular box design, reduce maintenance cost |

SOFTWARE SPECIFICATION :

| Language : English / Chinese |

| Unit Inch : system / Metric system |

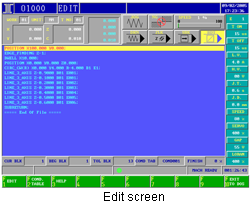

| Programming : Dialog programming / G/M code programming / background programming / expert system auto-programming / RS232/ Network |

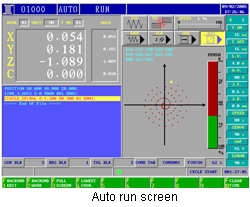

| Operation : mode Auto / Manual / Edit / Manual Data Input ( MDI ) |

| Screen function : Expert / Graph / Diagnostic / Alarm / Set |

| Software panel function : DRN / SBK / BDT / ZLK |

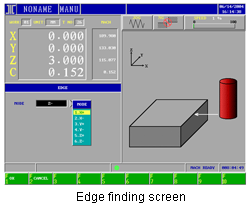

| Positioning function : Rim Searching / Groove Center Searching / Hole Center Searching / Outer Center Searching / Apex / Sparkle Tooling Correction |

| Machining function : Orbit Cutting / Cone / Planar Expansion Orbit / Vector Orbit / 3-Dimension Orbit / Machining Along Path / Time Limited Machining / Multi-Hole Macro / Multi-section Finishing / Cutting with C Axis |

| Offset function : Tool Length / Tool Radius / Gap / Thread |

| MLC function : I/O Point / C Point / S Point / A Point / Timer / Counter / Temporary Saver / D Temporary Saver / Real-Time Ladder Diagram Display |

| General function : Multi-Coordinate System / Coordinate System Zoom Scale / Coordinate System Rotation / Graph Rotation / Machining Path Display / User Macro Command / On-Line Instruction |

| E code number : 1000 |

AXIS CONTROL :

| Basic axis : 3 Axis |

| Extended axis : 1 ( C axis, optional ) |

| Numbers Of Basic Co-axis : 3 Axis |

| Number Of Simultaneously Driving Axis : At most 4 Axis |

| Number Of Hand Wheel's Controllable Axis : 3 Axis ( Optional for C Axis ) |

SYSTEM SETTING UNIT:

| Metric - Minimum Input Unit : 0.001 mm / Minimum Command Value : 0.001 mm / Maximum Stroke Setting : 9999.999 mm |

| English - Minimum Input Unit : 0.0001 inch / Minimum Command Value : 0.0001 inch / Maximum Stroke Setting : 999.9999 inch |

| Angle - Minimum Input Unit : 0.001° / Minimum Command Value : 0.001° / Maximum Stroke Setting : 359.999° |

G CODE TABLE :

| Positioning Function - Function : Rapid Positioning / No-Guard Rapid Positioning / Edge Finding / Groove Center Finding / Hole Center Finding / Outer Center Finding / Apex Finding / Home Origin Finding / Sparkle Tooling Correction / Automatic return to Reference Point / 2nd Reference Point Return |

| General Machining - Function : 3 Axis Linear Cutting / Clockwise Circular Arc Cutting / Counter-Clockwise Circular Arc Cutting |

| Orbit Macro Machining - Function : Circular Macro / Square Macro / Vector Macro / Fan-Shaped Macro |

| Loran Machining - Function : Standard Loran Machining / Loran Pattern Rotation / Plane Setting of Expansion Loran / Angular Loran |

| Multi-hole Macro Machining - Function : Linear / Circular / Arc / Square / Random Mode of Multi-hole Machining |

| Time Limited Machining - Function : Cutting Time Setting For Time Limited Machining |

| Macro - Function : Call Macro Command |

| Coordinate System Function - Function : Machine Coordinate System / Working Coordinate Systems / Polar Coordinate System Command / Zoom Scale / Coordinate System Rotation / Absolute/Incremental setting / Setting Coordinates of Current Position / Selection of Working Plane / English / Metric Conversion |

| Compensate Function - Function : Tool Radius Compensation / Tool Length Compensation |

| C Axis Function - Function : C Axis Home Origin Finding / C Axis Helical Machining / Helical Positioning / C Axis No-Guard Helical Positioning |

| Other - Function : Dwell / Data Setting / Stored Stroke Check Function |

| Pumping Mode - Function : Pumping Along Current Machining Axis / Pumping Upward Along Z Axis / Pumping Along Machining Path / Pumping to the center and then Along Current Machining Axis / 45°back to the Center and then Along Current Machining Axis |