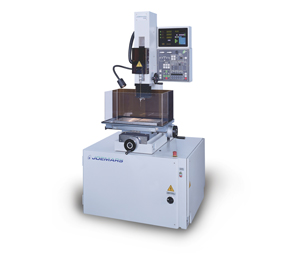

Super Drill EDM JM325DZ

Developed by a group of top engineers and technicians with rich on ground and theoretical experience in the field of Drill EDM, JM325DZ renders superb engineering supremacy and unmatched mechanical features to outstand others.

- Specs

- Accessories

- Features

- Controls

- Cut Samples

- Video

- Inquiry

MACHINE SPECIFICATIONS

| ITEM | UNIT | JM325DZ |

|---|---|---|

| Work table size | mm | 460 × 210 |

| X , Y travel | mm | 330 × 200 |

| Z Ram servo travel | mm | 345 |

| W axis | mm | - |

| Guide travel | mm | 150 |

| Max. workpiece weight | kgs | 100 |

| Electrode size | mm | Ø 0.2 – Ø 3.0 |

| Max. electrode length | mm | 400 |

| Ram platen to worktable | mm | 120 ~ 270 |

| Machining dielectric | Distilled water | |

| Capacity of dielectric | L | 10 × 2 |

| Machine weight | kgs | 620 |

| machine dimension | mm | 1090 × 1465 × 2070 |

GENERATOR

| ITEM | UNIT | JM325DZ |

|---|---|---|

| Power input | 200 / 220 / 346 / 380 / 415 / 440 3 phase VAC | |

| Max. power consumption | KVA | 3.5 |

| Max. peak current | A | 38 |

| Sparking condition number | 100 sets ( 0 ~ 99 ) | |

| Peak current setting | 15 steps ( 0.3 A ~ 38 A ) | |

| Capacitor setting | 16 steps ( 0 ~ 15 ) | |

| On time setting | 99 steps ( 1 ~ 99 ) | |

| Off time setting | 99 steps ( 1 ~ 99 ) | |

| Sparking gap setting | 16 steps (1 ~ 16) | |

| Servo sensitivity setting | 100 steps ( 0 ~ 99 ) |

* All specification and design are subject to change without notices.

STANDARD ACCESSORIES

| Tool box 1 Set |

| Stainless clamping kits 1 Set |

| Electrode holder Ø 0.2 ~ Ø 3.0mm 1 Set |

| Electrode ceramic guide Ø 1.0mm 1 Pc |

| Electrode tube Ø 1.0mm 10 Pcs |

| Dielectric tank ( 10 liter ) – For D / DZ only 2 Sets |

| Rubber water stopper 10 Pcs |

| Filter 1 Set |

| Operation manual 1 Set |

OPTIONAL ACCESSORIES

| Filter |

| Brass / copper electrode Tube ( Length 300 mm or 400 mm ) |

| Ceramic guide & rubber water stopper. |

| Range: Ø 0.2 ~ Ø 3.0mm, per 0.1 mm increment. |

FEATURES

| 100 Sets machining condition memories: Can store 100 sets user machining condition. "Fuzzy" control circuits: Only input ( A ) |

| Machining materials, ( B ) Electrode diameter, ( C ) Electrode wear. New starter learns how to operate on in 5 minutes. |

| Electrode will automatically retract to home point when arriving depth, greatly reduce moving time. |

| Z axies coordinate will automatically set to zero when finding edge. |

| " Off time " will be adjusted when machining is not stable, if unstable situation over a certain time, sparking will be stopped. |

| Special high pressure pump design, water come out quickly and with pressure releasing control system in order to reverse water without and dropping. |

| Machining parameters can be modified temporarily while machining, without affecting the stored parameter. |

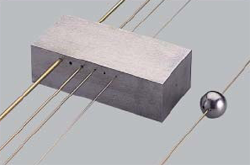

A WIDE RANGE OF APPLICATIONS 1

| Pre-hole drilling of workpiece for wire cut. |

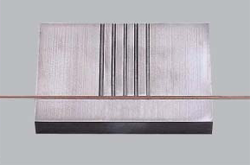

A WIDE RANGE OF APPLICATIONS 2

| Machining of coolant holes. |

A WIDE RANGE OF APPLICATIONS 3

| Deep hole drilling in ejector. |

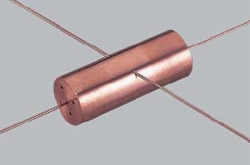

A WIDE RANGE OF APPLICATIONS 4

| Drilling flushing holes in copper electrode. |

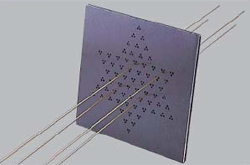

A WIDE RANGE OF APPLICATIONS 5

| Blind holes drilling. |

A WIDE RANGE OF APPLICATIONS 6

| Machining holes on inclined faces or in difficult position. |