Wire Cut EDM AWT 4S

Developed by a group of top engineers and technicians with rich on ground and theoretical experience in the field of wire cut edm, AWT 4S renders superb engineering supremacy and unmatched mechanical features to outstand others.

- Specs

- Accessories

- Features

- Controls

- Cut Samples

- Video

- Inquiry

MACHINE UNIT & FILTRATION SYSTEM

| ITEM | UNIT | AWT 4S |

|---|---|---|

| Max. work piece dimension ( W x D x H ) | mm | 750 x 650 x 245 |

| Max. work piece weight | kgs | 450 |

| X travel | mm | 450 |

| Y travel | mm | 300 |

| Z travel | mm | 250 |

| U travel | mm | 100 |

| V travel | mm | 100 |

| Drive system | AC servo motor | |

| Wire diameter | mm | Ø 0.15 ~ Ø 0.30 ( standard ) |

| Max. taper angle | mm | +/-24° / 80mm |

| Machine net weight | kgs | 2200 |

| Filter system capacity | L | 700 |

| Filter element | Paper filter | |

| Ion exchange resin capacity | L | 14 |

| Water quality control | Auto | |

| Water temperature control | Auto | |

| Machine layout dimension ( W x D x H) | mm | 2236 x 2308 x 2070 |

* All specification and design are subject to change without notices.

STANDARD ACCESSORIES

| Auto vertical alignment lig / 1set |

| Tool kit / 1set |

| Wire guide Ø 0.25 mm – 1set |

| Brass wire roll Ø 0.25 mm / 1 set |

| lon exchange resin / 1 set |

| Filter element / 1 set |

OPTIONAL ACCESSORIES

| Wire tension meter |

| Wire guide set Ø ( 0.15mm / 0.20 mm / 0.25 mm / 0.30 mm ) |

| Dielectric cooling unit |

| Consumable parts ( wire, flushing nozzles……etc. ) |

| Super fine finish circuit |

| Linear scale ( for X & Y axis ) |

| Auto voltage regulator ( AVR ) |

| 20 kgs wire loading system |

| The 6th axis ( The rotary B-axis ) |

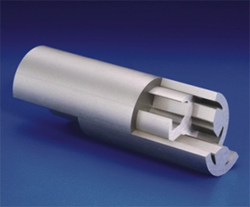

OPTIONAL APPLICATION – THE 6 TH AXIS APPLICATION ( The device should be ordered when order confirmed. )

| Joemars controller is required for the 6th application. |

| Maximum axes of control: 6 axes. ( X / Y / U / V / Z / B axis) |

| Simultaneously machining axes: 5 axes. ( X / Y / U / V / B axis) |

| Not only for single rotary, positioning and index functions but simultaneous movement with other axes. |

| Joemars own designed servo index system and controller system. |

| Direct drive by DDR motor, rotary positioning accuracy reaches 0.5 seconds. |

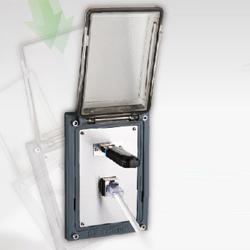

| The 6th Axis ( B-axis ) with “Grade IP68” – water proof design, no rusting concern. |

| Controller, rotary system, index plate and the related parts are all 100% designed and made in Taiwan! |

| B-axis is a separate unit and could be adopted upon request. It won't influence the original travels. |

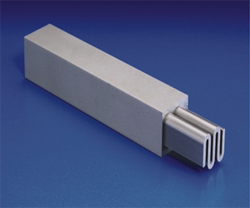

OPTIONAL APPLICATIONS - 20 KGS WIRE LOADING SYSTEM

| ( The device should be ordered when order confirmed. ) |

MECHANICAL FEATURES

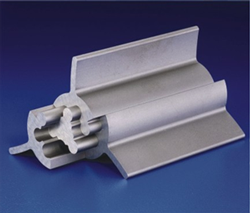

| Special upper / lower wire guide assembly, providing high-speed automatic wire threading in water and accuracy machining. |

| Simple and reliable Automatic Threading Device, applies high precision accuracy and easy for operator's maintenance. |

| Special anti-leaking system of low arm and work-tank, keeping axes movement smoothly. |

| Special cooling system for low arm, providing high accuracy required while machining. |

| Hardened Stainless work-table enhances surface rigidity and well-support for work-piece. |

MECHANICAL FEATURES 1

| PRECISE SERVO AND DRIVER SYSTEM |

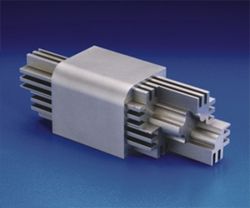

| Each axis uses high precision C1 class ball screw with grinded and sub-zero treatment with manual single shot lubrication system to control the temperature change and consume of parts. The procedures make the smoothness better and bring more accurate machining, bring a longer life time for ball screw and control the accuracy gap to happen. With high power and strong response AC servo motor, another optional can also be considered "Linear Scales" to make the total close loop circuit control. Our linear guide way adapt new generation high smoothness linear guide way, reduces the problem of friction and ensures the stability when making the machining. |

| HIGH RIGIDITY STRUCTURE |

| Well-balanced, box-type design casting of machine body ensures high thermal balance stability and rigidity. |

| U / V / Z axis all are located upper from the high rigidity of machine column and low arm applies with special thermal and hardened procedures, thus it does not get bend during machining with high water pressure. |

| WORK TANK FEATURES |

| Semi-Submerged water level can be set in the work tank to cover the work table, to control the working area's water temperature in good condition. |

| WELL-BALANCED TERRMAL DESIGN |

| The well-balanced mechanical structure design, casting applies thermal treatment and heat current procedure. Low arm with water cooling circulation equipment and combine with super anti-transform alloy material, to bring the high accuracy. |

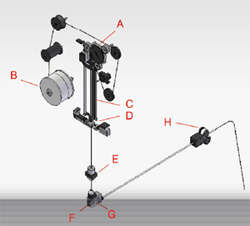

SIMPLE AND STABLE AUTOMATIC WIRE THREADING SYSTEM

| A. AC servo motors are used on machine, not only providing " Positioning & Tension " control with high reliability but enhancing the stability of wire tension. |

| B. DC motor control offers various settings for different wire diameters. |

| C. Air cools wire during wire annealing and then wire gets broken by melting, making no burrs at wire tip to enhance the reliability of wire threading. |

| D. Intelligent wire-cutting device, applying a proper voltage to cut different diameter of wire. |

| E. For AWT system, unique upper wire guide structure can make a high pressure water jet which achieves wire threading of wire diameter 0.15 ~ 0.3mm. |

| F. Special lower wire guide assembly offers high pressure water jet to assist the wire passing through the lower tube successfully. |

| G. Ceramic lower feed roller provides a smooth wire threading and brings a longer lifetime. |

| H. PWM DC wire collecting motor system provides a stable wire feed. |

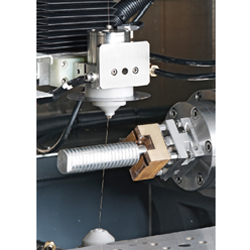

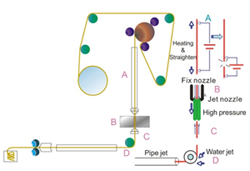

AUTOMATIC WIRE THREADING SYSTEM

| Wire snapped by melting |

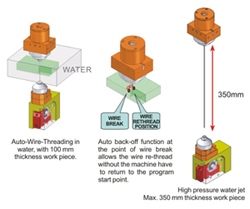

FEATURES OF AUTOMATIC WIRE THREADING

| A. Directly thread wire in submerged condition, saving the time and raising the working efficiency. |

| B. Wire threading at break point is achievable. |

| C. Upper water jet system achieves automatic wire threading with a thick workpiece. |

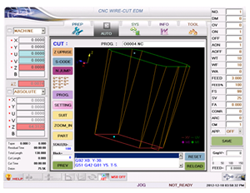

WINDOWS CONTROLLER

| Standard keyboard, mouse operation and touch screen, user friendly design. |

| 15" TFT-LCD screen, shows the better view of data and function needed. |

| Standard USB port, inputting NC programs quickly and conveniently. |

| Multiple language online change is available. |

| Built-in simple CAD / CAM software increases job efficiency. |

REMOTE CONTROL BOX ( AWT SERIES ONLY )

| All in One 5 axis LCD coordinate remote control box, operation done in one finger. |

SELF-GUIDED OPERATION INTERFACE

| User friendly interface, from calling NC programs to prepare to do cutting, is a total self-guided operation way to make the procedures easier and quicker. |

3D GRAPHICS

| 3D graphics simulation makes operators to recognize the job shape easily and avoid mistakes. |

CAD / CAM FUNCTION ( OPTION )

| From drawing to NC program, directly operate built-in CAD / CAM on machine. |

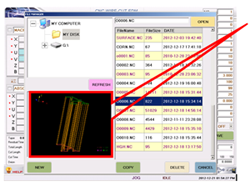

GRAPHICS PRE-VIEW FUNCTION

| Online drawing pre-view functions, easily to find the old NC programs which were executed before. |

DATA TRANSMISSION INTERFACE

| USB transmission interface, provides efficiency and convenience for operators. |

| Ethernet interface can link with PC to transmit NC programs. |

CNC UNIT & PROCESSING POWER SUPPLY

| CPU grade : Industrial grade Pentium 4 IPC 2.8 GHZ |

| Ram : 1GB |

| Storage device : CF card |

| Screen display : 15" TFT-LCD TOUCH SCREEN |

| Input means : Keyboard, Ethernet, USB |

| Pointing unit : Mouse, Touch Screen |

| Servo control mode : |

| Fully-closed circuit AC servo control ( Linear Scale is an option accessory ) *1 |

| No. of axis control : |

| 5 axes ( The 6th axis is an option accessory ) *2 |

| Min. input comment : 0.1 µm |

| Max. input comment : ± 9999.9999 mm |

| Graphic rotation : 0 ~ 360° |

| Storable machining condition : 10000 sets |

| *1 : Linear Scale option is for X/Y axis, need to be installed when order confirmed. |

| *2 : B-axis is made by Joemars, need to be ordered when order confirmed. |

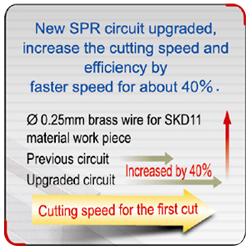

POWER UNIT SPECIFICATION

| Discharge circuit : High speed MOSFET |

| Discharge mode : AC non-electrolysis discharge |

| In gap max. average current : 25A |

| Intelligent OV circuit : For thin and thick machining |

| Stable discharge control : SPR circuit |

| Max. machining speed : 180 mm 2 / min |

| ( wire diameter : 0.25 mm BS, material : SKD11 ) |

| Required electricity : 3 phase, AC 220V / 380V / 415V / 440V,18KVA |

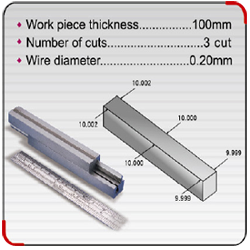

MACHINING SAMPLE ( MID ~ HIGH THICKNESS )

| Material:SKD11 |

| Work piece thickness:50mm |

| Wire diameter:Ф 0.25mm BS |

| Number of cuts: 3 cuts |

| Surface roughness:0.55 ~ 0.59µm / Ra |

MACHINING SAMPLE ( MID ~ HIGH THICKNESS ) 2

| Material:SKD11 |

| Work piece thickness:60mm |

| Wire diameter:Ф 0.2mm BS |

| Number of cuts: 3 cuts |

| Surface roughness:0.54 ~ 0.58µm / Ra |

MACHINING SAMPLE ( MID ~ HIGH THICKNESS ) 3

| Material:SKD11 |

| Work piece thickness:40mm ( Punch ) , 20mm ( Die ) |

| Wire diameter:Ф 0.25mm BS |

| Number of cuts: 3 cuts |

| Surface roughness:0.55 ~ 0.59µm / Ra |

MACHINING SAMPLE ( MID ~ HIGH THICKNESS ) 4

| Material:SKD11 |

| Work piece thickness:80mm |

| Wire diameter:Ф 0.25mm BS |

| Number of cuts: 3 cuts |

| Surface roughness:0.6 ~ 0.65µm / Ra |

MACHINING SAMPLE ( MID ~ HIGH THICKNESS ) 5

| Material:SKD11 |

| Work piece thickness:40mm |

| Wire diameter:Ф 0.2mm BS |

| Number of cuts: 3 cuts |

| Surface roughness:0.54 ~ 0.58µm / Ra |

THICK WORK PIECE CUTTINGS.

PCD、CBN APPLICATION

MACHINING EFFICIENCY

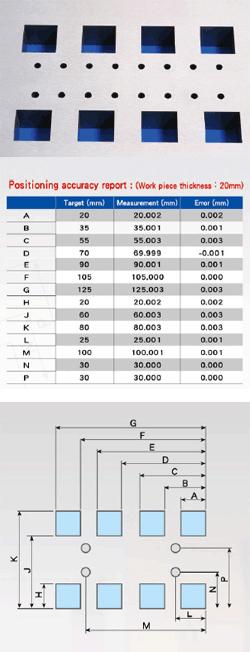

ACCURACY PERFORMANCE